Our partnership with Smart-tek Automated Services Inc.

In conclusion, at Gulf States Saw & Machine Co., our commitment goes beyond merely adopting new technologies. We strive to innovate and integrate these technologies in ways that redefine our industry’s standards, driving productivity, sustainability, and growth. Our ongoing investments in systems like the HK Smart Cell and Smart Tower Automated Loading Systems are pivotal in this strategy, helping us maintain our status as industry leaders and paving the way for future advancements that will continue to challenge the conventional and elevate the exceptional.

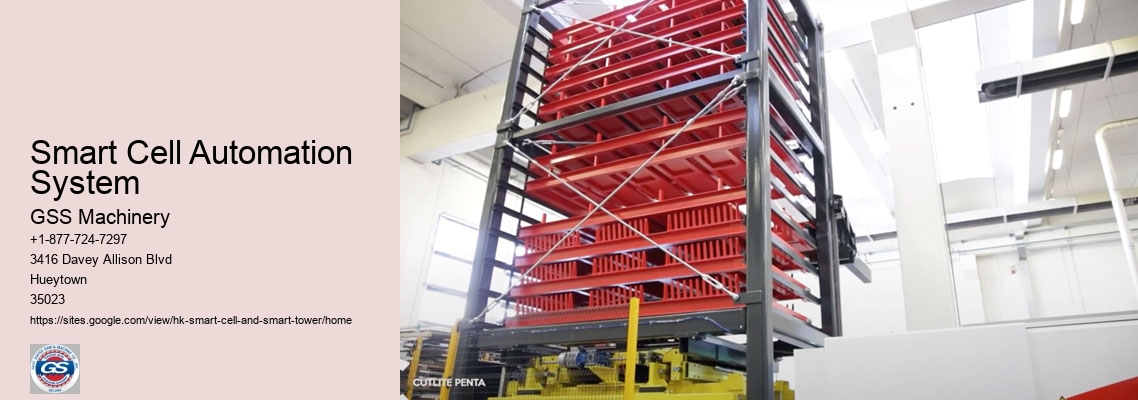

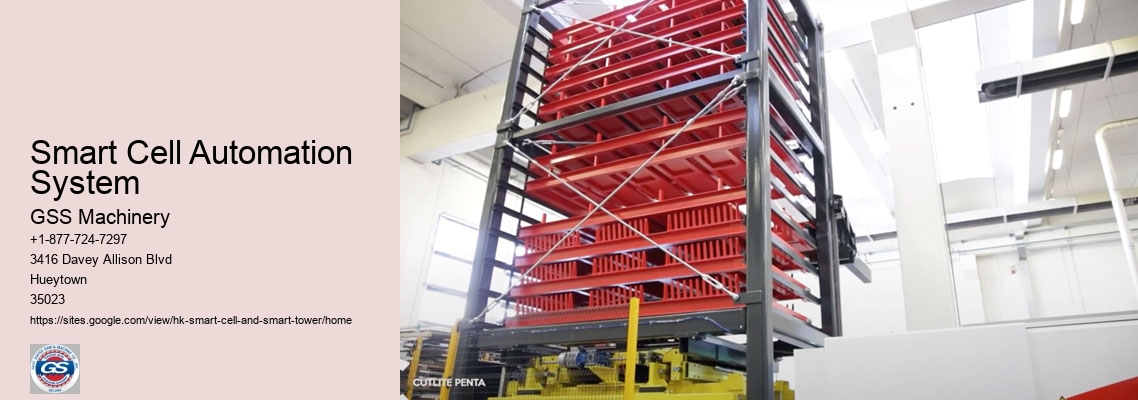

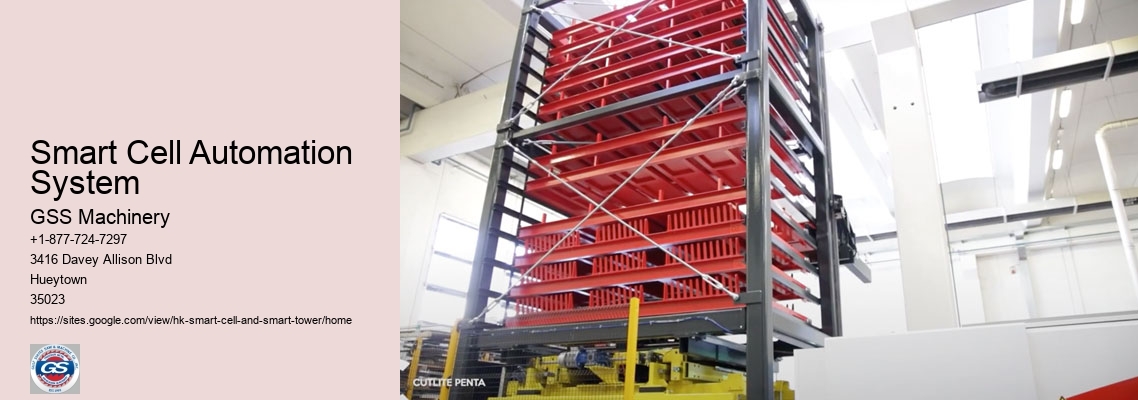

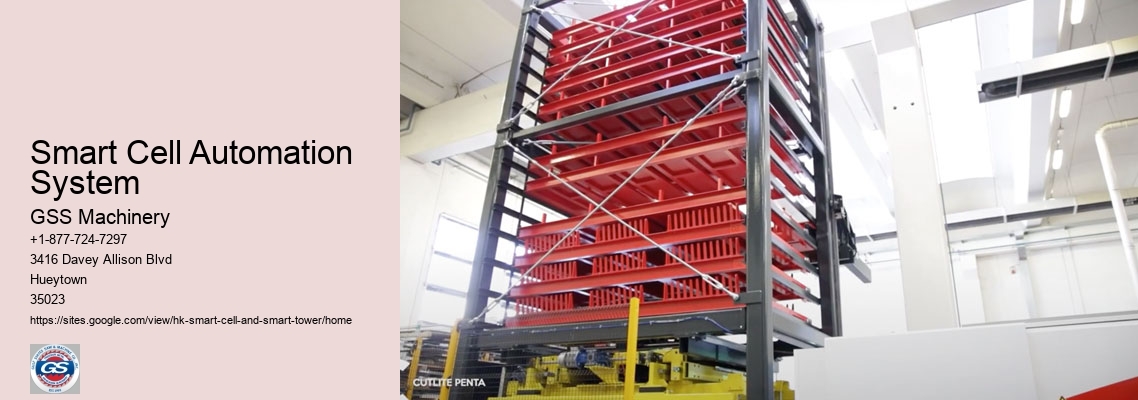

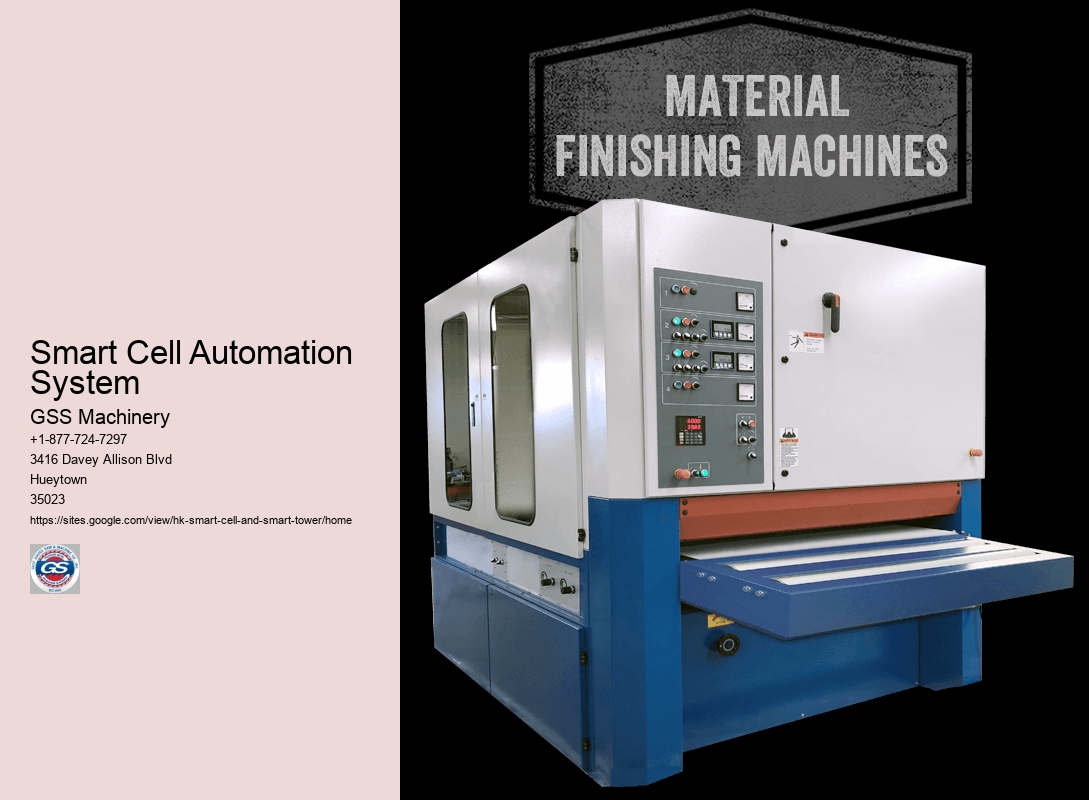

At Gulf States Saw & Machine Co., we stand proudly at the forefront of industrial progress, embracing cutting-edge solutions like the HK Smart Cell and Smart Tower Automated Loading Systems. These advanced technologies represent a significant leap forward, revolutionizing our material handling processes and driving unparalleled gains in productivity and safety across diverse sectors.

The integration of HK Smart Cell and Smart Tower Automated Loading Systems (Smart Tower Automated Loading Systems) offers an advanced solution for enhancing efficiency in warehouse and manufacturing environments. By centralizing control and automating the loading process, these systems significantly improve throughput and accuracy. With HK Smart Cell and Smart Tower Automated Loading Systems, businesses can achieve faster cycle times and reduced labor costs, while maintaining high levels of precision and reliability in their operations. This innovative approach to material handling is pivotal for industries looking to optimize productivity and streamline their logistical frameworks..The seamless integration of HK Smart Cell and Smart Tower Automated Loading Systems has reshaped how we approach logistics and inventory management.

Leveraging the HK Smart Cell & Smart Tower Automated Loading Systems, we've optimized space utilization and elevated the precision of our loading tasks. This intelligent system not only handles goods with finesse but also continually learns and adapts to its operational environment, perpetually refining its efficiency.

At the core of this technology lies the HK Smart Cell with Smart Tower Automated Loading Technology, boasting advanced sensors and software that orchestrate tasks autonomously, previously reliant on manual labor.

Several of our workstations now feature the HK Smart Cell and Smart Tower Auto-loading Systems, pivotal in managing high-volume tasks demanding precision and repeatability.

The integration of HK Systems AGV further amplifies our efficiency, with these automated guided vehicles seamlessly ferrying materials between production stages, eliminating the need for human intervention and streamlining our operations.

Our unwavering commitment to safety and precision is evident in our adoption of Cranesmart Load Cell technology. These devices ensure that loads are meticulously managed, preventing overloads and potential accidents. Similarly, the JR Automation Tote Stacker systems optimize storage solutions, maximizing vertical space and enhancing facility organization.

Critical to our operations are the components supplied by Load Cell Automation Direct. Their dependable load cells play a vital role in weighing and batching processes, guaranteeing accuracy and consistency in production.

The integration of Smart Load Cells has unlocked a higher tier of data precision, empowering automated decisions that fine-tune production workflows and elevate product quality.

At Gulf States Saw & Machine Co., we're proud to be pioneers in industrial innovation, embracing state-of-the-art solutions like the HK Smart Cell and Smart Tower Automated Loading Systems. Capacity These cutting-edge technologies mark a significant advancement, transforming our material handling processes and driving remarkable improvements in productivity and safety across various sectors.

The seamless integration of HK Smart Cell and Smart Tower Automated Loading Systems has completely revamped our approach to logistics and inventory management. By embracing this innovation, we've significantly reduced manual errors and supercharged the efficiency of our warehouse operations.

By leveraging the HK Smart Cell & Smart Tower Automated Loading Systems, we've optimized space utilization and enhanced the precision of our loading tasks. This intelligent system not only handles goods with finesse but also continually learns and adapts to its operational environment, continually refining its efficiency.

At the heart of this technology lies the HK Smart Cell with Smart Tower Automated Loading Technology, boasting advanced sensors and software that orchestrate tasks autonomously, previously reliant on manual labor.

Several of our workstations now boast the HK Smart Cell and Smart Tower Auto-loading Systems, playing a crucial role in managing high-volume tasks demanding precision and repeatability.

The integration of HK Systems AGV further amplifies our efficiency, with these automated guided vehicles seamlessly ferrying materials between production stages, eliminating the need for human intervention and streamlining our operations.

Our unwavering commitment to safety and precision is evident in our adoption of Cranesmart Load Cell technology. These devices ensure that loads are meticulously managed, preventing overloads and potential accidents. Reliability Similarly, the JR Automation Tote Stacker systems optimize storage solutions, maximizing vertical space and enhancing facility organization.

Critical to our operations are the components supplied by Load Cell Automation Direct. Their dependable load cells play a vital role in weighing and batching processes, guaranteeing accuracy and consistency in production.

The integration of Smart Load Cells has unlocked a higher tier of data precision, empowering automated decisions that fine-tune production workflows and elevate product quality. Similarly, the utilization of 6-axis Load Cells delivers crucial multi-directional force and torque measurements, indispensable for intricate assembly tasks.

At Gulf States Saw & Machine Co., we take pride in our commitment to cutting-edge industrial solutions, exemplified by our adoption of the HK Smart Cell and Smart Tower Automated Loading Systems.

JR Automation's Tote Stacker enhances warehouse operations by automating the stacking and storage of totes, reducing manual handling, and increasing storage density and retrieval speeds.

Smart-Tek Automated Services Inc. offers a range of services including the installation and maintenance of automated control systems for homes and businesses, focusing on enhancing operational efficiency and safety.

The HK Smart Cell provides centralized control and monitoring capabilities, allowing for seamless integration and coordination of automated tasks within industrial and manufacturing settings.

Automated Logic Room Sensors are used in smart buildings to monitor environmental conditions like temperature, humidity, and occupancy, which helps in optimizing energy usage and ensuring comfort.

Automated Parking Tower technology streamlines vehicle storage by automatically placing and retrieving vehicles in a multi-story storage facility, maximizing space usage and reducing the need for large parking lots.